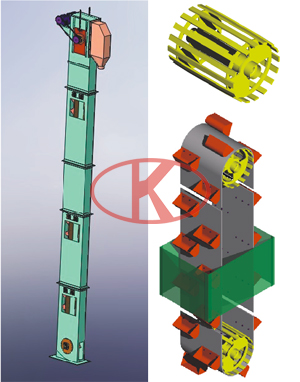

LDG hopper elevator

This elevator consists of upper area, middle casing, down district,(with tension roller), driving device(with transmission roller), tape, hopper. Characteristic as follows:

The casing is folded and welded structure. Maintenance door is set at the side, while active door is set in front and side of the casing.

Blanking by centrifuge gravity way.

Adopt polyester wire core exclusive conveyor belt, with high strength and stretch resistant.

The belt wheel is rat-caged structure, increase the friction between the type and belt wheel, automatically guide the elevating belt to gather to the middle and prevent running deviation, thus lengthen the lifetime, meanwhile prevent the dispersed shot to embed between the belt wheel and belt to effect transmission.

Impulse wheel is installed on the shaft under the elevator to test the working status of elevator, in order to feedback the signal to PLC processing timely and ensure safe operating of equipment by alarming.

Elevating quantity is retained of 10%.

|

Model |

Belt’s Width(mm) |

Power(kw) |

Speed(m/s) |

Lifting Scale (t) |

Lifting Height (m) |

|

LDG160 |

200 |

4 |

0.84 |

15 |

≤ 20 |

|

LDG250 |

300 |

7.5 |

1.05 |

60 |

≤ 30 |

|

LDG350 |

400 |

7.5 |

1.25 |

90 |

≤ 30 |

|

LSC hopper elevator |