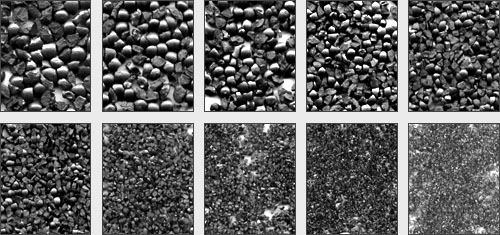

The steel grit is granule shape made from the crushed high carbon cast steel, divided into three hardness (LSGH,LSGL,LSGP)to meet different requirements. The processed sand is separated into ten classes of SAE standard for sandblasting application.

Products of different sizes and harness are used according to different circumstances, like stick cylinder engraving and granite cutting, etc.

Our steel sand adopts the production process of Japan New East, the hardness, density and micro-structure of products are consistent and homogeneous, and meanwhile have good strength and durability. These features have good shot blasting cleaning function.

Steel sand is widely used in the pretreatment of steel work piece coating, the most applied way in this process is sandblasting booth with recycling device. The angular sand and related hardness will make the cleaning speed fast and can recycle effectively.

Steel sand is widely used in the sand cleaning of castings, the work piece will have casting sand adsorbed onto the castings in excessive high temperature, out of the range of steel shot cleaning capacity, at this time, steel sands can only be used.

When the shot blasting equipment that using steel shots can’t clean the steel work piece effectively, steel sand can be used.

Industry application

Aviation, automobile industry, sandblasting/paint spraying manufacturer; consumable manufacturing, container manufacturing/ repairing, casting

Granite / stone cutting, ship building and repairing, petroleum and gas pipeline, workshop maintaining and metal processing.

Process application range

Surface pretreatment of coating, casting sand-cleaning, pipeline descaling, etc.

Instruction and performance

Instruction and performance

When used to clean and remove the rust and oxide layer, the effect will be best using the centrifuge shot blasting equipment.

|

class |

LSG120 |

LSG80 |

LSG50 |

LSG40 |

LSG25 |

LSG18 |

LSG16 |

LSG14 |

LSG12 |

LSG10 |

|

profile |

<10 |

10 |

15 |

20 |

30 |

50 |

60 |

70 |

80 |

90 |

|

cleaning speed |

fast |

|

damage rate |

about 1% of every circulation |

abrasive property

hardness(HRC)

LSGP

LSGL

LSGH |

46-50

56-60

63-65 |

micro structure

LSGP

LSGL

LSGH |

Martensite and bainite

Martensite and bainite

martensite and Austenite |

|

shape |

with angle |

Carbon content% |

0.85-1.2 |

|

volume density(kg/M3) |

3700 |

Silicon content% |

0.5-1.0 |

|

granule S.G. |

>7.6 |

Manganese content% |

0.6-1.0 |

|

color |

Gray, silver, blue |

Sulfur content% |

<0.05 |

|

standard |

SAE |

Phosphorus content% |

<0.05 |

Casting steel sands

Applied to shot blasting machine, shot blasting equipment, shot blasting cleaner, shot blasting machinery, shot peening and blasting, shot peening machine, shot peening equipment, sand peening machine, sand peening equipment, steel pretreatment line, steel plate pretreatment line, abrasive in steel structure pretreatment line.

Application of steel sand

|

steel sand |

application |

LSSG-2.0

LSSG-1.7 |

Sand-cleaning and rust removal of large-sized casting, cast steel, cast iron pipe, malleable iron, large-sized casting, heat treated parts |

LSSG-1.4

LSSG-1.2 |

Sand-cleaning and rust removal of medium and large iron casting, steel casting, malleable iron, steel billet, steel plate, forging, heat treatment parts. |

LSSG-1.0

LSSG-0.7 |

Sand-cleaning and rust removal, shot peening, roll etching of medium and small iron casting, cast steel, malleable iron, medium and small forging, heat treatment parts, steel plate, profile steel, structure steel, copper alloy casting. |

|

LSSG-0.4 |

Sand-cleaning and rust removal, surface treatment, shot peening, roll etching of small casting, forging, heat treatment parts, aluminum alloy casting, steel plate, strip steel, steel pipe. |

LSSG-0.4

LSSG-0.3 |

Sand-cleaning and rust removal, surface treatment, shot peening, roll etching of copper alloy casting, sheet metal, stainless strip steel. |

LSSG steel sand: the hardness of this kind of steel sand is higher than GP steel sand, but in the sandblasting process, edges will be lost. It applies to the oxide layer removing and pretreatment of steel surface.

LSGH steel sand: the hardness of this kind of steel sand is high, edges will be kept in the re-sandblasting process, especially effective to the regular fluffing surface. GH steel sand when used in the shot peening, should be considered of the occasion that construction requirement is prior to price factors (like roll processing of cold rolling plant). This kind of steel shot is mainly used in compressed air shot peening equipment.

|

name |

steel sand |

|

item |

LSGP |

LSGL |

LSGH |

|

hardness

|

HRC46—50

HV449—509 |

HRC50—60

HV509—713 |

HRC63—65

HV795—856 |

|

Micro structure |

Uniform backfire martensite |

|

Density |

≥7.4g/cm3 |

|

shape |

angular |

|

Chemical

content

|

Carbon |

0.85—1.20 %

|

|

Silicon |

0.60—1.20 % |

|

Manganese |

0.50—1.20 % |

|

Sulfur |

≤0.05 % |

|

Phosphorus |

≤0.05 % |

规格选择依据

|

steel sand |

application |

|

LSG10 |

Sand-cleaning and rust removal, oxide layer surface cleaning of large-sized casting, cast steel, steel structure, large-sized casting, heat treated parts. |

|

LSG12 LSG14 LSG16 |

Sand-cleaning of large and medium size casting, oxide layer removal of forging and heat treatment, rust removal, surface strengthening of steel plate, profile steel and steel structure. |

|

LSG18 LSG25 |

Sand-cleaning of medium and small size casting, rust removal of forging and heat treatment, steel plate, steel pipe, profile steel and steel structure, surface treatment and stone cutting before coating. |

|

LSG18 LSG25 |

Sand-cleaning, oxide layer removal of large-sized casting, forging, heat treatment parts, aluminum cooper alloy casting, steel plate, strip steel, steel pipe. Surface strengthening of spring chain, and grinding process of stone cutting. |

|

G40 G50 G80 G120 |

Sand-cleaning and rust removal of alloy casting, sheet metal, strip steel, small stainless casting. Surface treatment of spring strengthening before coating, increase the roughness in order to increase the adhesion. |

particle distribution list

|

Sieve NO |

Sieve hole diameter |

Specs |

|

steel sand |

LSG10 |

LSG12 |

LSG14 |

LSG16 |

LSG18 |

LSG25 |

LSG40 |

LSG50 |

LSG60 |

LSG120 |

|

7 |

2.8 |

all pass |

|

|

|

|

|

|

|

|

|

|

8 |

2.36 |

|

all pass |

|

|

|

|

|

|

|

|

|

10 |

2.00 |

80% min |

|

all pass |

|

|

|

|

|

|

|

|

12 |

1.70 |

90% min |

80% min |

|

all pass |

|

|

|

|

|

|

|

14 |

1.40 |

|

90% min |

80% min |

|

all pass |

|

|

|

|

|

|

16 |

1.18 |

|

|

90% min |

75% min |

|

all pass |

|

|

|

|

|

18 |

1.00 |

|

|

|

85% min |

75% min |

|

all pass |

|

|

|

|

20 |

0.850 |

|

|

|

|

|

|

|

|

|

|

|

25 |

0.710 |

|

|

|

|

85% min |

70% min |

|

all pass |

|

|

|

30 |

0.600 |

|

|

|

|

|

|

|

|

|

|

|

35 |

0.500 |

|

|

|

|

|

|

|

|

|

|

|

40 |

0.425 |

|

|

|

|

|

80% min |

70% min |

|

all pass |

|

|

45 |

0.355 |

|

|

|

|

|

|

|

|

|

|

|

50 |

0.300 |

|

|

|

|

|

|

80% min |

65% min |

|

all pass |

|

80 |

0.180 |

|

|

|

|

|

|

|

75% min |

65% min |

|

|

120 |

0.125 |

|

|

|

|

|

|

|

|

75% min |

60% min |

|

200 |

0.075 |

|

|

|

|

|

|

|

|

|

70% min |

|

LSGB |

2.0 |

1.7 |

1.4 |

1.2 |

1.0 |

0.7 |

0.4 |

0.3 |

0.2 |