|

|

|

|

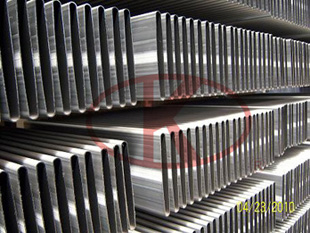

Large Flat tube online melt ejection spraying and fill aluminum |

|

Switchable dual system online spraying |

Judging from the category of utility air cooling equipment manufacturing, the vast majority of air cooling power station with single-row tube of direct air cooling, core elements of single-row tube is the base tube , the flat tube ,large flat tube.Flat tube's raw materials is the single aluminum steel clad plate

Aluminum steel clad plate By high-frequency welding and nip forming, in the process of welding, the surface layer of the composite aluminum damaged, after welding welds needs to be processed (dig scars), to ensure that when the fin tube welding of tube and fins fully fit .But the impact of processing,after digging scars , aluminum layer will be planed off, affecting the quality of welding pipes and fins,reducing the effect of finned tube heat exchangers and corrosion resistance.To overcome the follow-up questions, planing scars need to re-fill with aluminum!Re-fill aluminum coating is directly related to the quality of the welding performance of fin-and-tube, heat transfer and corrosion resistance.

We apply the most advanced online coating technology to the project, designed for users of the automatic fill aluminum spray equipment systems, advanced spraying equipment to protect the bonding strength between coating and substrate, coating of high density and width of sound.Meanwhile, during the fill aluminum process will produce large amounts of harmful gas and aluminum dust, low cost design of the latest ideas, energy and environmental protection dust removal system solves the issues, so that the production area clean environment to avoid the system operator and the host hazard. The company can see what others can not,Shanghai Liangshi Blasting and Coating Equipment Co., ltd. in their domestic ,the first domestic production line and Shanghai on the first line that work with spraying equipment, can be said to be a recognition of our technology and equipment!

☆☆ Note: detailed configuration of thermal spraying and thermal spraying process please download the Special Edition of the overview; professional and technical consultation: 13917088713,021-51035200 call to Mr.Ge☆☆