Supercritical Power Pipe Wall Shot Blasting Machine

As the growing up of the supercritical power station and related industries, heat exchanger and steam pipes face with a high demand of its stainless steel pipe inner wall’s oxidation resistance in working under a high temperature and high pressure situation, which demands advanced stainless steel pipe production equipment. Such as SUS321HTB of 18-8 model stainless steel pipe, used in boiler, heater and reheater in thermal power, deliveries high temperature (higher than 540℃ ) and high pressure(greater than 25MPa ) steam for long time. Its inner wall is easy to be oxidized and peeling, which makes pipe clogged and equipment damaged. According to many years research, stainless steel pipe inner wall can be enhanced its oxidation resistance by shot-peening. Experiments shows, stainless steel pipe inner wall changes its surface micro structure after using shot-peening, and significant changes happened in various elements enrichment layer (especially Cr) greatly enhance the oxidation resistance. Its thickness of oxide layer is 0.07%~1.7% to the inner wall without shot-peening, and it would not be peeling. it’s the good effect of shot-peening. Therefore special stainless steel pipe production factories in China usually require using this kind of small diameter stainless steel inner wall shot-peening equipment, to enhance the oxidation resistance and hardness of inner wall.

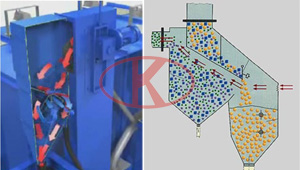

Supercritical Power Station Used Small Diameter Stainless Steel Pipe Inner Wall Shot Peening

SH Liangshi combined related shot-peening technology in home and board, researched and developed inner wall shot-peening equipment over 2 years, finally manufactured small diameter (DN22mm~40mm) stainless steel pipe inner wall shot-peening equipment.